The wood industry is inherently rich and diverse, encompassing everything from raw materials, crafting techniques, production processes, to the final output products. Hence, there are numerous specialized terms used in various sectors. In this article, let’s explore and clarify all these terms with Techno Wood.

1. Wood grain

Here’s a commonly used keyword in the wood industry, appealing to both professionals and amateurs alike. “Wood grain” refers to the unique patterns, stripes, or figures visible on the surface of wood. These patterns create a distinctive and aesthetically pleasing appearance on wood-based products, such as furniture, hardwood flooring, construction materials, and decorative items.

Wood grain can be categorized into various types depending on the type of wood and how the wood is cut. Some common types of wood grain patterns include plain-sawn, quarter-sawn, and engineered patterns like laminate or veneer (thin wood glued onto another surface).

Wood grain not only enhances the aesthetic appeal but also adds uniqueness and beauty to wooden products, thereby increasing their aesthetic and market value.

Thus, wood grain is often highlighted as a strength or advantage when introducing a particular wood product.

2. Heartwood

Certainly, in the wood industry, we often encounter questions like, “Is this product good, does it have heartwood?” So what exactly is heartwood ?

The term “heartwood” typically refers to the central part of a wood plank or material, distinguished from the outer layer known as sapwood. Heartwood is usually softer and has a more intricate cellular structure compared to the outer layer, called sapwood.

When people discuss heartwood in various contexts, it may relate to how wood is used in art, craftsmanship, or landscaping. Depending on the context, “heartwood” can carry different meanings, but it generally pertains to the inner, softer, and more complex structure of wood compared to the exterior.

For the question “Does it have heartwood?”. In this context, heartwood is understood as a defect in a wood product, indicating that the wood material originates from a tree with a hollow or decayed center due to growth characteristics or prolonged insect infestation.

Thus, if wood material is cut from a tree with defected heartwood, such as veneered plywood, it will leave indentations ranging from minor to significant on the surface. This leads to subsequent processes like filling and sanding to achieve a smooth and finished surface. If the heartwood defect is severe, we may need to discard those flawed wood parts and avoid including them in the production process.

In summary, the phrase “having heartwood” signifies a defect in a wood product, contrasting with wood grain.

Left image: Heartwood and Sapwood.

Right image: The tree has defected heartwood.

3. Sapwood

From the image above, sapwood is the lighter-colored portion that lies adjacent to the bark of the tree, responsible for nourishing the entire tree structure. During the growth process of the tree, sapwood also acts as a conduit, transporting essential nutrients and minerals needed for the tree’s survival. This part becomes particularly attractive to pests, such as termites. Hence, sapwood is strictly avoided in selecting wood for interior furniture.

On a cross-sectional view, the heartwood appears darker than the sapwood. In some species, there is often the phenomenon of hollow core wood. There is no direct correlation between the growth in diameter of the tree trunk and the volume of sapwood and heartwood. Some species don’t develop a hollow core, while others form it very early, making the sapwood layer very thin (e.g., thorny bamboo and mulberry trees).

Sapwood is typically utilized and processed separately to produce thin veneers that contribute to the papermaking, cardboard, or fuel material industries.

Similar to “having heartwood,” the term “having sapwood” is also widely used in the wood industry, both for raw and interior wood. Simply put, a regular cut into the tree trunk will produce a piece of wood containing both heartwood and sapwood.

Depending on the subsequent processing, you can obtain a piece of wood completely devoid of sapwood, or it may retain some, or even all, depending on the requirements of the customer, like “can you accept sapwood?” or “what percentage of sapwood is acceptable?” Based on these specifications, we can offer a more reasonable price for products compared to cases where sapwood is entirely unacceptable.

In summary, “having sapwood” is a keyword that indicates a defect in a product, similar to “having heartwood,” and is prevalent across all wood industries, from split acacia wood to acacia veneer boards, pallets, and interior furniture.

4. Wood Knot

The term “knot” is extensively used in the timber industry, referring to a section of wood or timber where a branch has grown. When these branches are cut off or die, they remain as a knot on the piece of wood, appearing as an encircled area or protrusion.

Due to its different structure and density compared to the surrounding wood, knots can pose challenges during processing and softening of the wood. In some instances, knots can diminish the aesthetic value of the wood, especially when used for decorative or furniture purposes. However, in certain types of wood, such as pine, knots can contribute to a natural beauty, adding to the unique character of the wood.

Knots are primarily categorized into two types, and these terms are commonly used in the wood industry:

4.1 Live Knot

A live knot is present when the branch section of the wood is still alive. Consequently, some live attributes of the branch, such as color or moisture, persist within the knot. Live knots are usually softer and more susceptible to environmental influences than dead knots. Since they are alive, live knots can change in color, size, or hardness over time.

4.2 Dead knot

A dead knot forms when the branch section of the wood has died and no longer grows. Dead knots are typically harder and exhibit less variation in color or size compared to live knots. Because they are dead, dead knots tend to resist environmental factors better than live knots. However, in certain cases, dead knots can decay or peel away from the main wood, creating voids.

In the production of split acacia wood, veneer boards, and other related industries, encountering knots is inevitable. Differentiating between live and dead knots is crucial as they impact the quality and properties of the final wood product. When using wood, dead knots are often preferred due to their stability and greater durability compared to live knots.

In conclusion, the term “knot” is usually a keyword that denotes a defect in the product.

Distinguish between Live Knots and Dead Knots

5. Finger Joint

The term “finger joint” refers to a technique where two wooden components are joined together through a precise woodworking process. This involves combining a concave wooden strip with a convex one to ensure a tight fit, accurate down to the millimeter.

Crafting a finger joint demands significant physical and mental effort from craftsmen due to its intricate and precise nature. Despite the challenges, the advantages of using finger joints are substantial. The joints ensure a solid connection even if the wood pieces might not share the same grain or structure.

In woodworking and design, finger joints are considered an art form due to their high utility, aesthetic appeal, and ability to significantly enhance product longevity. When employing finger joints, there’s often no need for screws or nails to bind two wooden components together. The appearance of finger joints can vary based on the aesthetic requirements of the product, offering flexibility in design.

From household items like everyday beds, where finger joints securely connect various sections, to wooden toys, where they adeptly connect limbs and body parts, the applications of finger joints are vast and versatile. In the realm of engineered wood production, specifically laminated boards, two primary types of finger joints are prevalent:

- Vertical Finger Joint (Top Finger): This refers to the method of joining pieces vertically.

- Horizontal Finger Joint (Side Finger): This involves the horizontal joining of components.

As illustrated, the horizontal finger joint often offers superior aesthetics since it conceals the joint, making it less visible on the board’s surface. While vertical joints might be slightly more cost-effective than horizontal ones, the latter has largely replaced the former due to its enhanced appearance and functionality.

The finger joint is intricately designed, enhancing both the strength and aesthetic appeal of the product.

Comparison images of the “top finger” and “side finger” joints in wood planks.

You can see the “top finger” joint on the surface of the board, while the “side finger” joint is visible on the side.

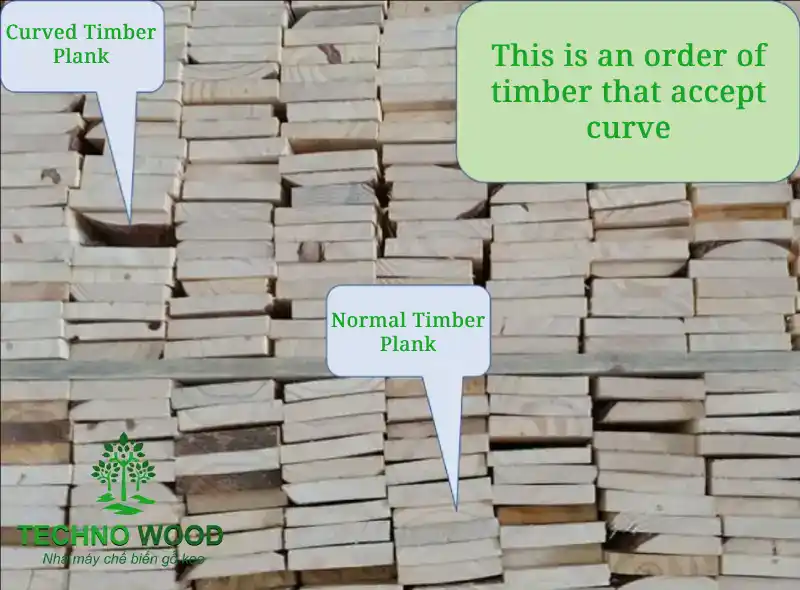

6. Curved, elliptical, warped

This keyword is usually use for Acacia timber.

When splitting a tree trunk lengthwise, the inner boards produce a square shape with sharp edges. Since the tree trunk has a round shape, the outer split boards will have one square corner, while the other corner remains rounded, resulting in an elliptical shape. This elliptical part is referred to as being “curved” or “warped”.

These split boards affected by curving or warping can still be used if the client doesn’t have excessively high standards for the finished product. For instance, pallets made from a mixture of regular split timber and those with “lẹm” or warping have minimal impact on load-bearing capabilities but may slightly affect the aesthetics of the pallet. Additionally, strategic placement can hide the warped portions, ensuring aesthetic appeal.

Thus, when ordering split timber, terms like “accepting curve” or “not accepting curve” will often be included in the specifications. Naturally, in orders that accept curve”, we can offer a more competitive price due to reduced sorting processes in production. (Place your order now!)

7. Kết luận

Above, Techno Wood has covered key technical terms in the timber industry related to all of our three product categories: Acacia Timber, Acacia Finger Joint Boards, and Acacia Pallets.

The timber industry is vast, with many specialized terms used across various product contexts. Techno Wood looks forward to presenting more detailed articles on this in future posts. Thank you all for visiting our website and reading through the articles!